Certified Professional Geologist

a Limited Liability Company

RESEARCH | EXPLORATION | DISCOVERY

928-525-6563

<

>

The second book ever printed (1556) by Johannes Gensfleisch zur Laden zum Gutenberg was De Re Metallica by Georgius Agricola or Geog Bauer. Agricola is known as the father of mineralogy. It was translated into English in 1912 by Herbert (31st President of the United States) and Lou Hoover .

The translation was a project started at Sanford University, when

Hoover was a professor of mining. Hoover’s lectures were published in a volume called “Principals of Mining”.

Below are some on the printed pictures from the Hoover translation and are available online.

This is a picture showing the methods for locating mineral deposits. Note the two dousers (left central) and the investors (lower left).

The picture below shows slucing for gold. What should be noted in that sheep skins were used for the trapping of metals from the slucing operations. The person at the barrel is washing the sheep skins to remove the heavy metals for later processing. The picture was provided in the reverse.

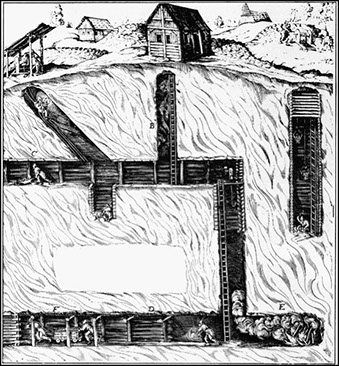

This picture shows the typical mining that had been used since the Egyptians and for the most part has not changed today. At the lower right hand corner, a fire had been set against the mining face. Since explosives had not been invented, fire was used to crack the rock for mining with picks and shovels.

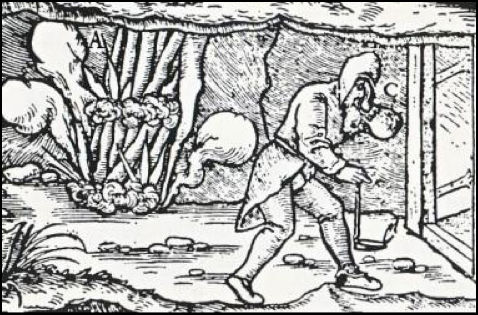

This picture shows the fire setter with an oil lamp and a skin or flask with air, so that, he can get out to fresh air.

AIr pumps to push fresh air into mines with bad air.

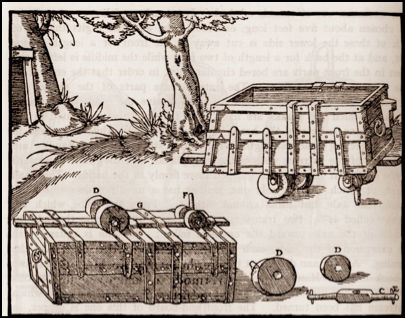

Ore carts have not changed in basic design for more than 1,000 years, just the materials they are made from. In the 1500’s, everything was wood with metal straps to keep it together.

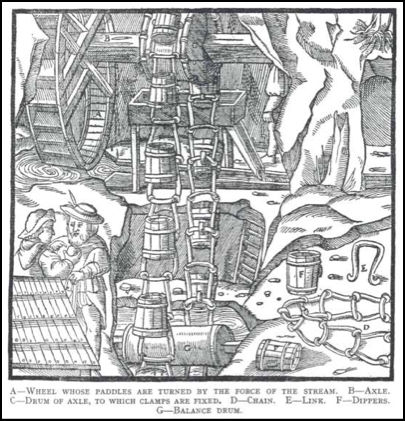

This design is one that the Romans are reported to have use. A series of buckets on a water wheel to lift mined material to the surface.

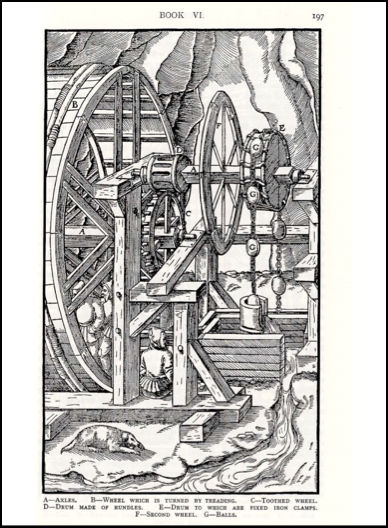

Dewatering mines were problems and here are two solutions that were in common use in the 1500’s.

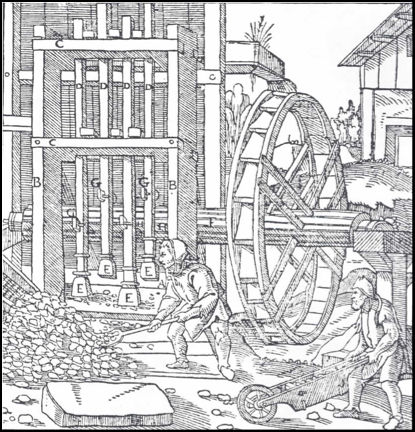

Extraction of metals from the rock has always been a problem. Before the Roman’s, most of the ore was broken down by hand. The Roman’s invented the first Stamp mills and were in wide spread use by the 1500’s. The method of breaking down the rock into small pieces did not change until the early 1800’s.

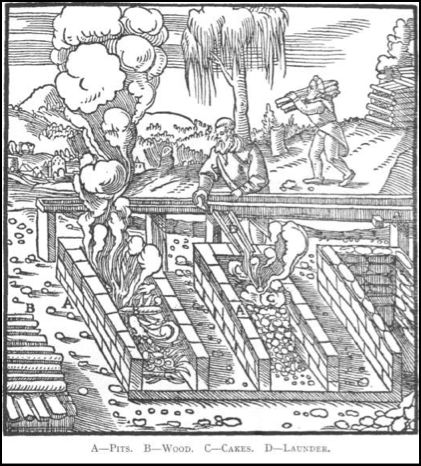

One the early forms to extract metals from the broken rock was to place the ore in long “Burn Pits”. The ore was covered in wood or coal and set afire. These pits were placed on hill sides, so that the liquid metals would flow downhill and pool at the bottom forming a matte or cement. The pooled metals at the bottom were typically 50% to 60% pure and needed additional smelting.

In this picture, a Burn Pit is shown in the upper right. The central part of the picture shows a man cleaning up the matte/cement, before it is placed into a smelter.

The English translation of De Re Metallica by Hoover is still available and a good read. Not much has changed.